Introduction of the Researches

Thermal Energy Engineering Laboratory(Ito Lab.)

Biomass fuel is paid much attention as one of the energy sources that reduce the amount of fossil fuel used and suppress global warming. In our laboratory, briquette manufacturing conditions and combustion methods that enable efficient and effective use of high-density solid biomass briquettes are developed. The effects of scale, density, and water content of briquette on internal heat transfer, and on ignition and combustion characteristics are investigated. The possibility of a new solid fuel combustion method that facilitates combustion control by burning from one end of the briquette is also studied.

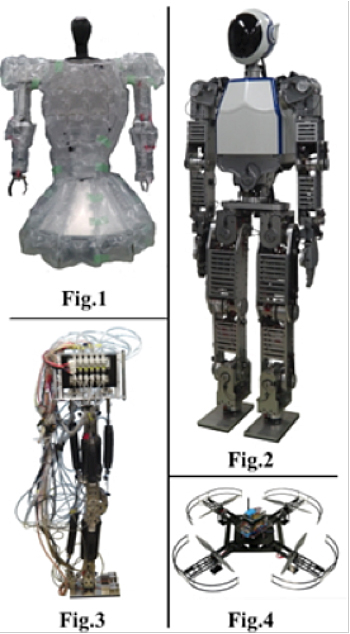

Robotics Laboratory(Lim Lab.)

Our laboratory’s aim is to develop human-robot coexistence robots that can support human beings’ day-to-day activities. Our research focuses on robot mechanisms, trajectory generation, control rules, emotional interactions, human safety system, and environmental recognition, among others. For example, we developed a robot that is able to ensure human safety even when it accidentally collides with a human being (shown in Fig. 1). When a robot moves within a confined area, such as our living space, it is possible that the robot will run into objects and human beings within the space. To ensure human safety, our robot is equipped with a passive collision force suppression mechanism, which does not rely on sensors. We have also developed a biped humanoid robot that can adapt to the human living environment (shown in Fig. 2). This robot stands at 1.66 m, weighs 64.5 kg, and consists of 42 degrees of freedom (including 6 degrees of freedom in each leg, 3 degrees of freedom in the waist, 7 degrees of freedom in each arm, 5 degrees of freedom in each hand, and 3 degrees of freedom in the neck). It is able to carry out dynamic walking (i.e. forward walking, backward walking, and lateral walking) on flat roads and is capable of gripping various objects. Other creations include entertainment robots (such as animal or insect robots), jumping robots (Fig. 3), flying robots (or drones) (Fig. 4), emotion expressing robots, and artificial intelligent robots.

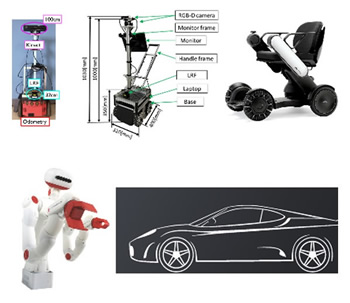

Robotics Control Systems Laboratory(Egami Lab.)

Mechanical engineering is the engineering of making things and moving them. In our laboratory, we are developing robots with new functions and conducting research to move them as desired.

As an example of specific development, when the space elevator is realized, we are developing an experimental climber considering what kind of function the climber needs. We are also conducting research on applying this to infrastructure inspection robots and construction support robots (Fig. 1).

Using the path control method developed in our laboratory, we have also developed a device that allows the ball to draw the desired path on the plate, and have achieved high-precision control that cannot be achieved by humans (Fig. 2).

We have developed an inverted-pendulum electric wheelchair that can be operated by body movements for healthy elderly people, etc., and have realized agile and delicate movements by body movements, and we are also developing a step-overcoming assistance mechanism. (Fig. 3).

In addition, we are also conducting research on welfare robots such as the development of a robot hand that has a simple structure using an iris mechanism and can grip all around (Fig. 4 is a photograph of holding a boiled egg).

Intelligent Machine Laboratory(Zhang Lab.)

In our laboratory, we apply artificial intelligence (AI) technologies to conduct research on intelligent robotics, intelligent information processing, and autonomous driving. A significant feature of our research lies in the multimodal relationships between robots and environments or users, making the robots always be considerate to all users and pedestrians around. We focus on how to efficiently understand the situations and status in the information space that includes humans, robots, and surrounding environments, and how to conduct smooth communications between humans and robots.

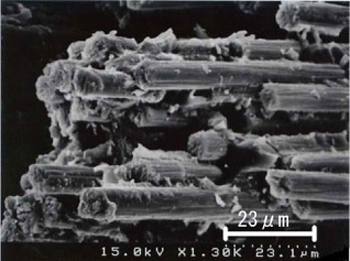

Composite Materials Laboratory(Takemura Lab.)

In this Laboratory, Fiber reinforced Plastics are focused because of high specific strength and high specific stiffness. Since Composite materials are made of several raw materials, the fracture mode is very complex. The information of crack progression process is important. So, we study the fracture process of composite materials and try to improve their mechanical properties. In addition, we study the mechanical properties of green composite whose reinforcement is natural fiber and matrix is biodegradable resin in the viewpoint of environment friendly materials.

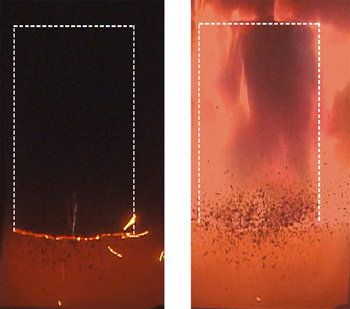

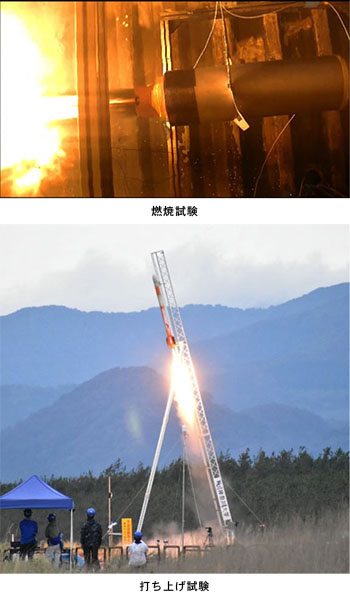

Aerospace Structure Laboratory(Takano Lab.)

Aircraft and spacecraft are required to be lightweight and highly reliable, and for that purpose, advances in structural design are indispensable. On the other hand, although computer analysis methods have made great progress, there are still unsolved fields such as the breakage phenomenon called buckling of thin-walled structures and the statistical evaluation of joint strength and strength. Our laboratory is engaged in research in these unsolved fields. In recent years, the development of microsatellite at universities has been active, but the opportunities are limited because they are launched by carpooling large rockets. Therefore, to launch a micro satellite inexpensively and quickly, development of ultra-small rocket, engine combustion test (upper figure) and rocket launch test (under figure) are also conducted. In addition, interfacial sliding analysis of fiber composite materials is performed using a computer.

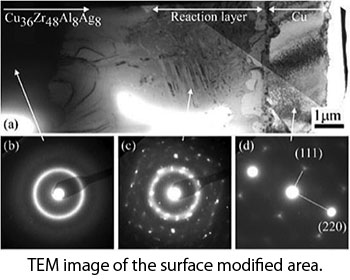

Functional Material Processing Laboratory(Terajima Lab.)

Recent research has focused on bulk amorphous alloys, which are generally called metallic glasses. Our research covers the development of new alloys, and their material processing, fibers, nanoparticles, and surface modification (fig.1). Metallic glasses possess unique properties, such as high mechanical strength, low elastic coefficient, small solidification shrinkage, and high resistance to corrosion. These properties originate from the amorphous structure and are not found in crystalline alloys. Usually, metallic glasses exhibit a large viscous flow in the supercooled liquid region. The flow can be exploited to fabricate three-dimensional shapes such as semispheres and small gears. These features open up new applications for this next-generation engineering material.

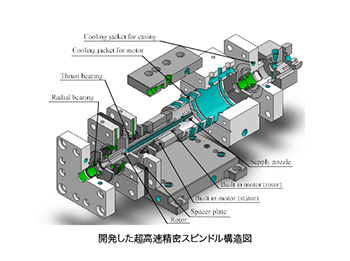

Ultra-Precision Machine Systems Laboratory(Nakao Lab.)

Our main research field is machine tools and precision machining, which are based on a state-of-the-art technology regarding mechanical design and machining. In particular, we are developing an ultra-precise “Spindle” that determines the machining accuracy of machine tools. Figure shows a structure of ultra-precision and high-speed spindle developed in our laboratory. The spindle was developed for precise machining of advanced materials. This spindle is equipped with aero hydrostatic bearings and a built-in high-speed motor. Furthermore, it is equipped with shaft-bore water cooling system to improve temperature stability.

In addition to development of spindle, “Temperature characteristics of machine tools”, “Precision machining for advanced materials”, ”Grinding and polishing of advanced materials for IT industries” and “Automatic violin playing robot” are our research projects.

Fluid Engineering Laboratory(Nakanishi Lab.)

We investigate the flow around a power generation unit with counter-rotating propellers to utilize tidal stream power. Figure shows the streamlines around the power unit set in the tidal stream direction obtained by the numerical simulation. We also study flow characteristics in hydraulic turbines to improve their performance and develop a trash removal device suitable for impulse turbines.

Thermal Science Laboratory(Haramura Lab.)

We have investigated the heat transfer mechanism in transition boiling where dry and wet areas coexist. Solving on inverse heat conduction problem, local heat fluxes were estimated from temperature histories at multiple locations. A number of thermocouples were created in a single plane by diffusion bonding (Fig. 1). This type of junction is stress-proof and has a high response. Figure 2 shows the behavior of liquid on the surface as the system pressure decreased suddenly and a single vapor bubble covered the surface. Figure 3 shows the variation in heat flux. The contribution of the triple contact line, which is the boundary between liquid and vapor phases on the surface, is about 24 kW per unit length of the contact line and per unit temperature difference.

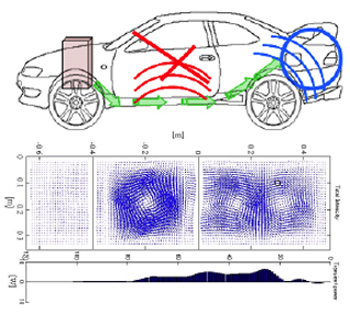

Mechanical Dynamics Laboratory(Yamazaki Lab.)

Our study focuses vibration and acoustic energy flow. For example, as shown in above figure, vibration propagated through the body of a car from the engine is made to radiate not to the interior of a car but to the trunk room by structure design of a car to silence the interior.

The below figure shows a structure made by connecting three plates and gives an idea of vibration isolation method. This idea is that if the vortex-typed energy flow is induced in the center plate, vibration propagated from the right plate to the left plate decrease. The combination of this idea and inducing the straight-typed flow is deriving the design method of the body to silence the interior by using vibration isolation and acceleration.